IS 15582

IS 15582 Hexagon Flange Bolts

Dimensions of IS 1862 Studs

All dimensions in millimetres.

z according to IS : 1368-1967. Dimensions of ends of bolts and screws

x according to IS : 1369-1975. Dimensions of screws thread run-outs and undercuts

x1 = normal ≈ 2.5p thread run-out as per IS : 1369-1975.

Dimensions Table - size range 3 to 14 mm

| Nominal size d h13 | M 3 | (M 3.5) | M 4 | (M 4.5) | M 5 | M 6 | M 8 M 8 x 1 |

M 10 M 10 x 1.25 |

M 12 M 12 x 1.25 |

(M 14) (M 14 x 1.5) |

||

| b+2P - 0 | For / < 125 | 12 | 13 | 14 | 15 | 16 | 18 | 22 | 26 | 30 | 34 | |

| 125 </< 200 | - | - | - | - | - | - | - | 32 | 36 | 40 | ||

| b1(js16) | Type A | Nom | 3 | 3.5 | 4 | 4.5 | 5 | 6 | 8 | 10 | 12 | 14 |

| Max | 3.3 | 3.88 | 4.38 | 4.88 | 5.38 | 6.38 | 8.45 | 10.45 | 12.55 | 14.55 | ||

| Min | 2.7 | 3.12 | 3.62 | 4.12 | 4.62 | 5.62 | 7.55 | 9.55 | 11.45 | 13.45 | ||

| Type B | Nom | 4.5 | 5 | 6 | 7 | 7.5 | 9 | 12 | 15 | 18 | 21 | |

| Max | 4.88 | 5.38 | 6.38 | 7.45 | 7.95 | 9.45 | 12.55 | 15.55 | 18.55 | 21.65 | ||

| Min | 4.12 | 4.52 | 5.62 | 6.55 | 7.05 | 8.55 | 11.45 | 14.45 | 17.45 | 20.35 | ||

| Type C | Nom | - | - | 8 | - | - | - | 16 | - | 24 | - | |

| Max | - | - | 8.45 | - | - | - | 16.55 | - | 24.65 | - | ||

| Min | - | - | 7.55 | - | - | - | 15.45 | - | 23.35 | - | ||

Dimensions Table - size range 16 to 39 mm

| Nominal size d h13 | M 16 M 16 x 1.5 |

(M 18) (M 18 x 1.5) |

M 20 M 20 x 1.5 |

(M 22) (M 22 x 1.5) |

M 24 M 24 x 2 |

M 27 (M 27 x 2) |

M 30 M 30 x 2 |

(M 33) (M 33 x 2) |

M 36 M 36 x 3 |

(M 39) (M 39 x 3) |

||

| b+2P - 0 | For / < 125 | 38 | 42 | 46 | 50 | 54 | 60 | 66 | 78 | 78 | 84 | |

| 125 </< 200 | 44 | 48 | 52 | 56 | 60 | 65 | 72 | 78 | 84 | 90 | ||

| For l > 200 | 57 | 61 | 65 | 69 | 73 | 79 | 85 | 91 | f | 103 | ||

| b1(js16) | Type A | Nom | 16 | 18 | 20 | 22 | 24 | 27 | 30 | 33 | 36 | 39 |

| Max | 16.55 | 18.55 | 20.55 | 22.65 | 24.65 | 27.65 | 30.65 | 33.8 | 36.8 | 39.8 | ||

| Min | 15.45 | 17.45 | 19.35 | 21.35 | 23.35 | 26.35 | 29.35 | 32.2 | 35.2 | 38.2 | ||

| Type B | Nom | 24 | 27 | 30 | 33 | 36 | 40.5 | 45 | 49.5 | 54 | 57 | |

| Max | 24.65 | 27.55 | 30.65 | 33.8 | 36.8 | 41.3 | 45.8 | 50.3 | 54.95 | 57.95 | ||

| Min | 23.35 | 26.35 | 29.35 | 32.2 | 35.2 | 39.7 | 44.2 | 48.7 | 53.05 | 56.05 | ||

| Type C | Nom | 32 | - | 40 | - | - | - | - | - | - | - | |

| Max | 32.8 | - | 40.8 | - | - | - | - | - | - | - | ||

| Min | 31.2 | - | 39.2 | - | - | - | - | - | - | - | ||

Note :

Sizes shown within brackets are of second preference.

The run out in the metal end of the stud is to be considered only up to the last scratch of the thread and does not include any unthreaded extruded portion adjacent to the run-out

Types

Three types as follows:

Type A - b1 ≈ 1 d, suitable for use in steel.

Type B - b1 ≈ 1.5 d, suitable for use in cast Iron.

Type C - b1 ≈ 2 d, suitable for use in aluminium alloys.

Preferred length size combinations for type A and type B studs

| l | M 3 | (M 3.5) | M 4 | (M 4.5) | M 5 | M 6 | M 8 M 8 x 1 |

M 10 M 10 x 1.25 |

M 12 M 12 x 1.25 |

(M 14) (M 14 x 1.5) |

M 16 M 16 x 1.5 |

(M 18) (M 18 x 1.5) |

M 20 M 20 x 1.5 |

(M 22) (M 22 x 1.5) |

M 24 M 24 x 2 |

(M 27) (M 27 x 2) |

M 30 M 30 x 2 |

(M 33) (M 33 x 2) |

M 36 M 36 x 3 |

(M 39) (M 39 x 3) |

| 14 | ||||||||||||||||||||

| 16 | ||||||||||||||||||||

| 20 | ||||||||||||||||||||

| 25 | ||||||||||||||||||||

| 30 | ||||||||||||||||||||

| 35 | ||||||||||||||||||||

| 40 | ||||||||||||||||||||

| 45 | ||||||||||||||||||||

| 50 | ||||||||||||||||||||

| 55 | ||||||||||||||||||||

| 60 | ||||||||||||||||||||

| 65 | ||||||||||||||||||||

| 70 | ||||||||||||||||||||

| 75 | ||||||||||||||||||||

| 80 | ||||||||||||||||||||

| 85 | ||||||||||||||||||||

| 90 | ||||||||||||||||||||

| 100 | ||||||||||||||||||||

| 110 | ||||||||||||||||||||

| 120 | ||||||||||||||||||||

| 130 | ||||||||||||||||||||

| 140 | ||||||||||||||||||||

| 150 | ||||||||||||||||||||

| 160 | ||||||||||||||||||||

| 170 | ||||||||||||||||||||

| 180 | ||||||||||||||||||||

| 190 | ||||||||||||||||||||

| 200 | ||||||||||||||||||||

| 225 | ||||||||||||||||||||

| 250 | ||||||||||||||||||||

| 275 | ||||||||||||||||||||

| 300 |

Note :

All dimensions in millimetres.

Sizes shown within brackets are of second preference.

Preferred lengths are between the stepped bold lines.

Preferred length size combinations for type A and type B studs

| l | M 4 | M 8 M 8 x 1 |

M 10 M 10 x 1.25 |

M 12 M 12 x 1.25 |

M 16 M 16 x 1.5 |

M 20 M 20 x 1.5 |

| 25 | ||||||

| 30 | ||||||

| 40 | ||||||

| 60 | ||||||

| 80 | ||||||

| 100 | ||||||

| 120 | ||||||

| 140 | ||||||

| 160 | ||||||

| 200 |

Note :

All dimensions in millimetres.

Preferred lengths are between the stepped bold lines.

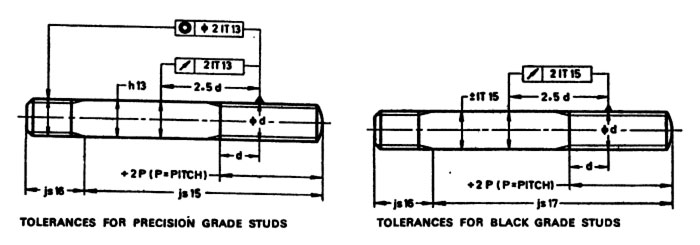

Tolerances

Mechanical Properties

- Type A and Type B studs, made from steel, shall conform to property classes 4.6, 6.6, 8.8 and 10.9 of IS : 1367 - 1967 'Technical supply conditions for threaded fasteners (first revision)'

- Type C studs, made from steel, shall conform to property classes 4.6, 6.6 and 8.8 of IS : 1367 - 1967.

- General Requirements - In regard to requirements not covered in this standard, the studs shall comply with the requirements of IS : 1367-1967.

- Sampling - The sampling and criteria of acceptance shall be in accordance with IS : 2614 - 1969 'Methods for sampling of fasteners (first revision).

- Designation - Shall be designated by the name, type size, nominal length, number of this standard grade and symbol for mechanical property class.

Example :

A stud Type A, size M5, nominal length 25 mm, precision grade and mechanical property class 8.8 shall be designated as:

Stud A M5 x 25 IS : 1862 - P 8.8